Efficient Milking increases the profitability of the whole dairy.

Efficient Milking increases the profitability of the whole dairy.

Planning of the overall project is very important. Independent from the chosen milking system (i.e. double 12 herringbone or rotary parlour) all aspects of the project have to match. Coordination of the number of cows in the pens, cow traffic, holding areas, return lanes, selection and treatment areas make daily work easier and more efficient. (Marc Benninghof, Bevern/Niedersachsen)

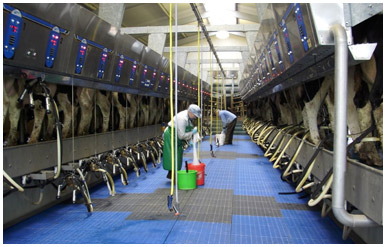

Planning and layout of the milking parlour focuses on labour comfort to ensure quality and efficiency of the milking process. The spacious design of the milk houses simplifies ventilation and the quality of natural lighting.

Fans and radiant heaters allow for control of temperatures to the seasons of the year. Entering the parlour without steps and a movable soft floor provides more employee comfort.

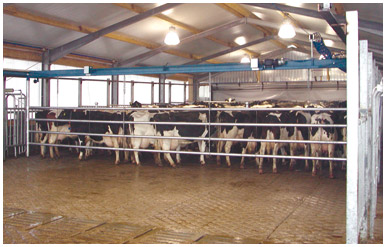

During construction there are opportunities to make cow traffic more efficient. For example upward sloping holding areas help to point the cows uphill toward the parlour and thus increases parlour flow. An automatic crowd gate supports the milker and helps with cow flow and calmness. Holding areas have to be spacious, well-ventilated and have to provide perfect cow traffic to the parlour.

External rotary parlour with 50 stalls

Double 24 side by side parlour

A large holding area ensures easy access to the parlour

External rotary parlour with 60 stalls

Robotic milking system

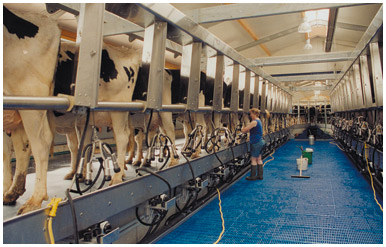

Progressive milking parlour with high worker productivity

Good working ergonomics increase the work efficiency at the milking

Double 16 herringbone with rapid exit

Double 12 herringbone

Side by side parlour with a central pit